|

|

Post by vespasco on Mar 14, 2015 19:15:21 GMT

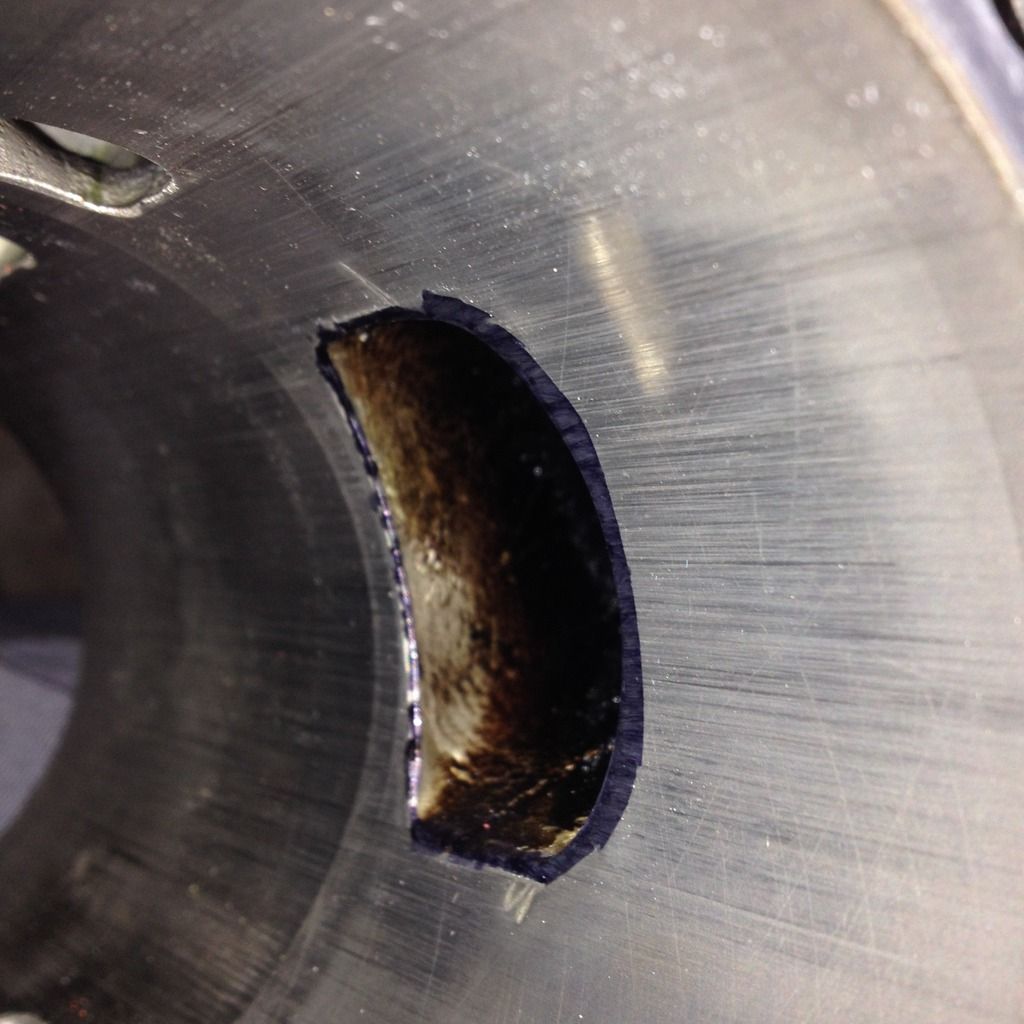

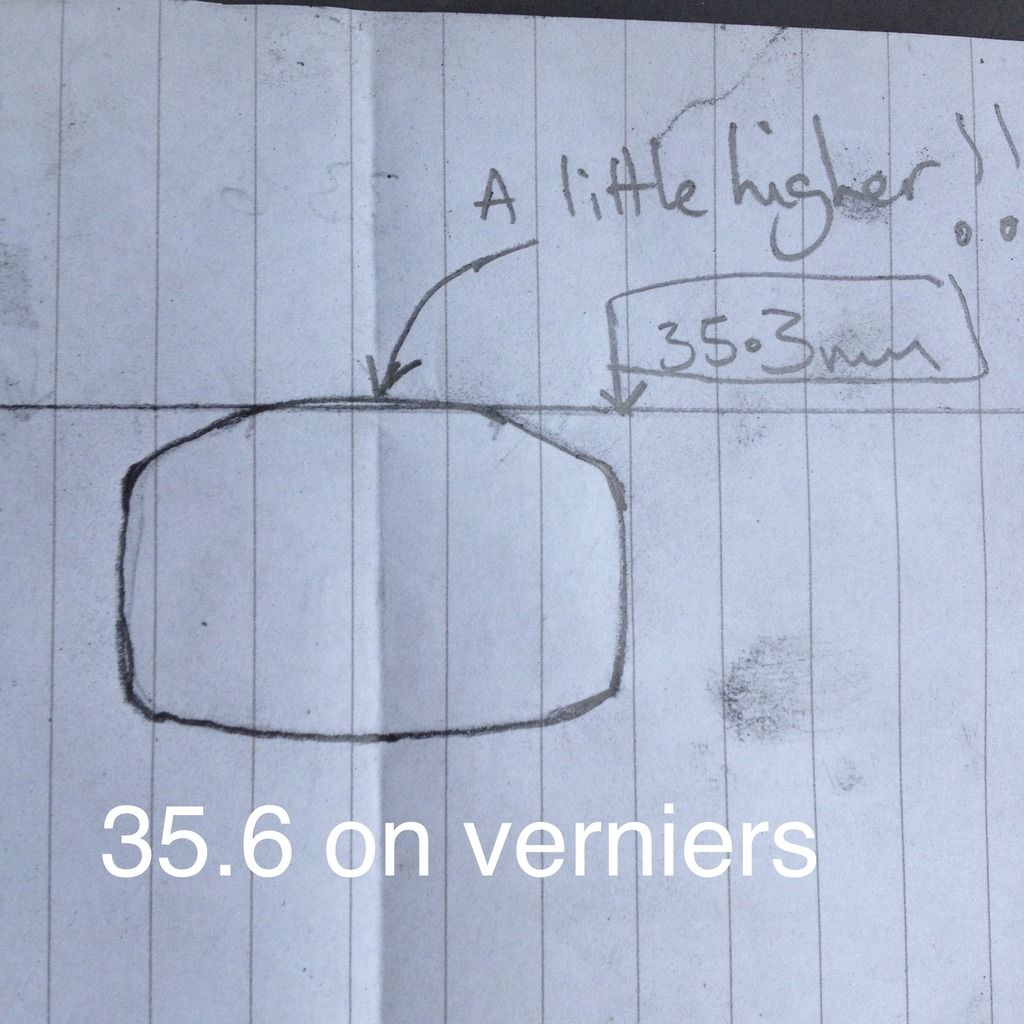

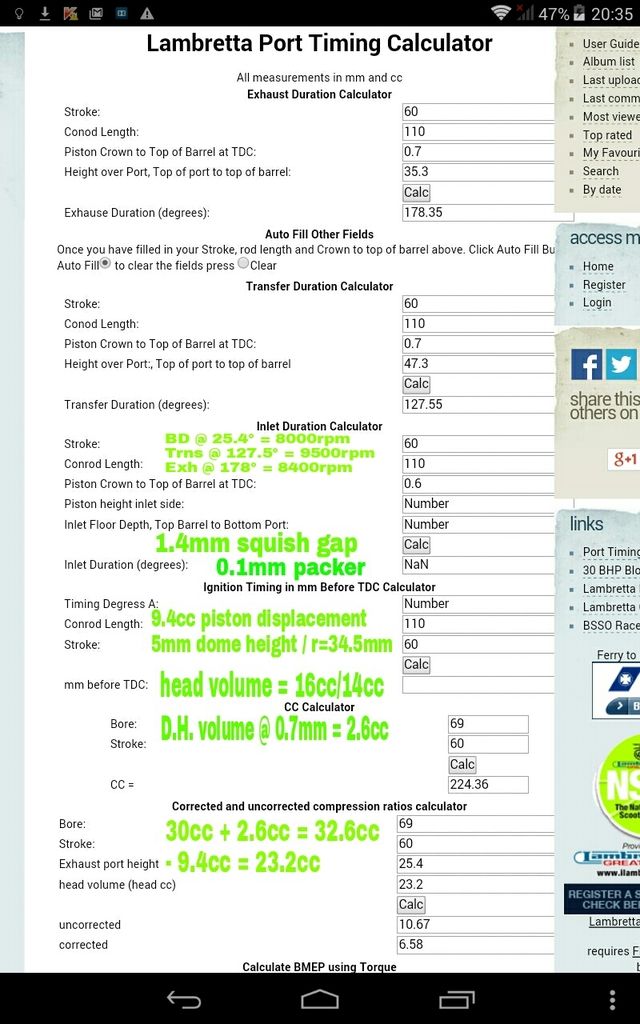

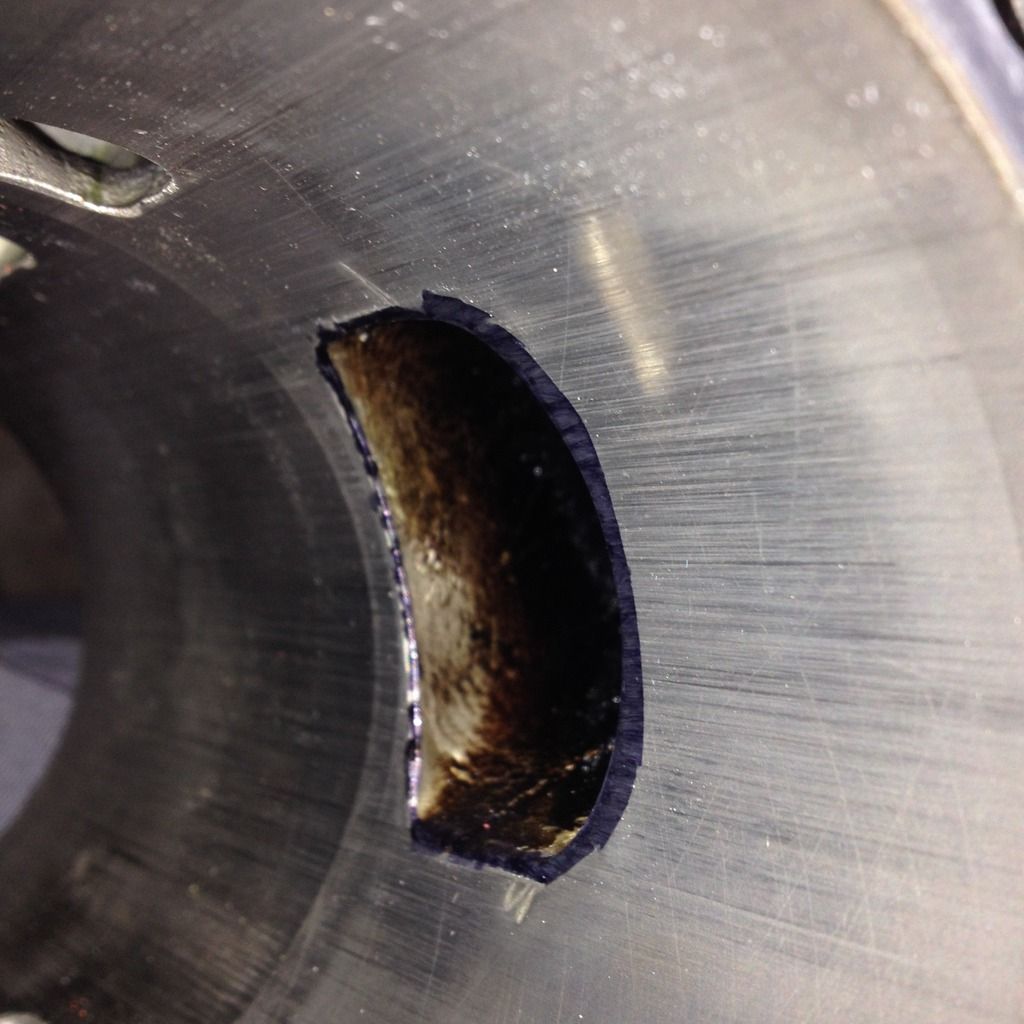

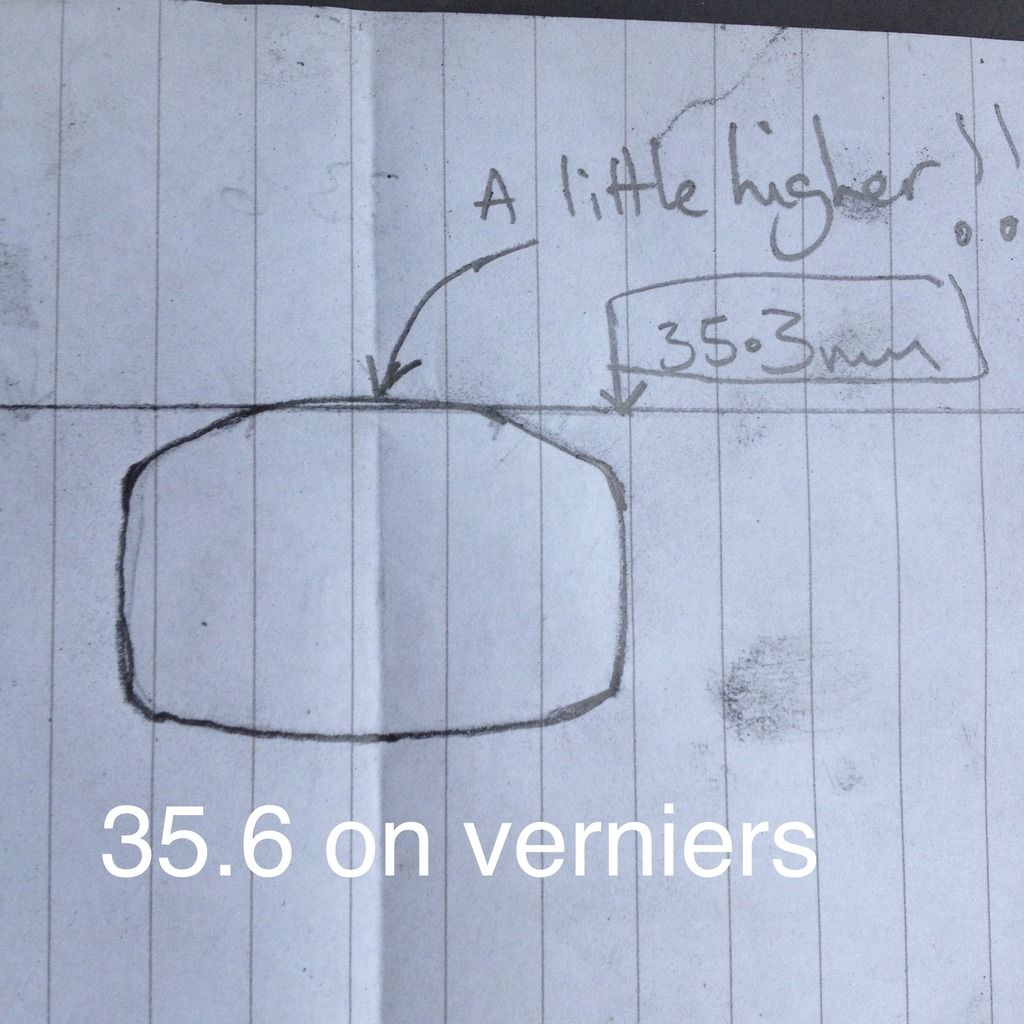

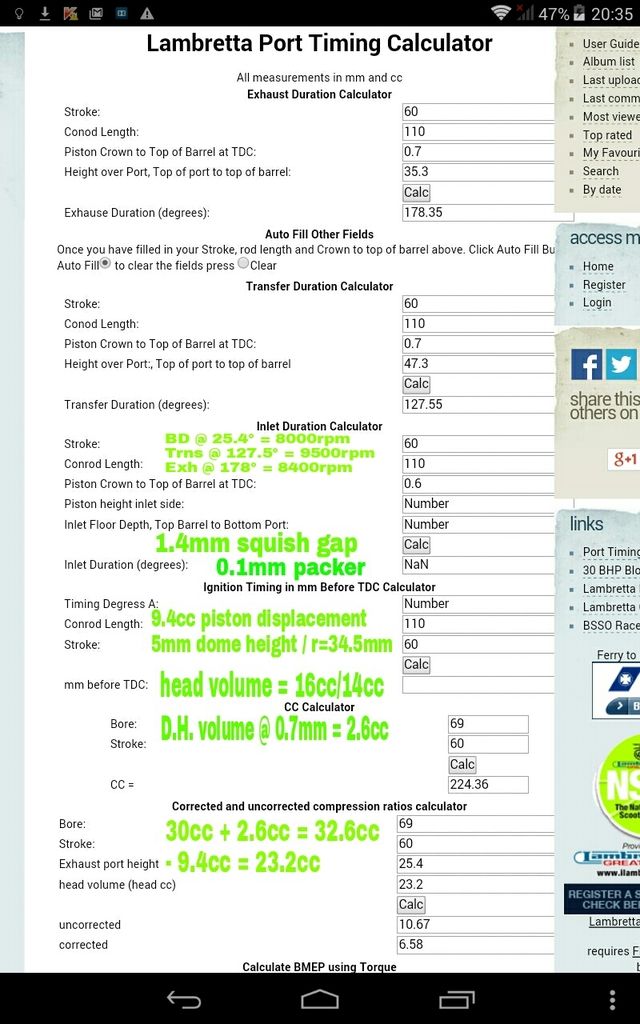

Cylinder stud sleeves worked suprisingly well  and will be used again! (these were plastic pen top lids that happen be a good diameter for this, drilled out to 8mm/8.5mm.  There was indeed a leak, from the head, hence the sudden pinking. I should have re-torqued a bit earlier! It was on the side of the cylinder/head you cant quite see when its all together! There was a small leak on the base too. Or at least i noticed the gasket sealant was wet! But no signs of blow by. Any views on using no gasket? I do have some cheapo 0.1mm gaskets! After i took the cylinder off there was lots of 2 stroke in the cylinder and on the piston/ in the cylinder ports. More than id expect to see at least? If i was to look at this, for the first time, without knowing any previous history, i may have guessed it was running on 3% oil!? (It runs 2%) My speedo cable is broken. I never noticed a small tear in the outer, a few inches up from the hub end.  The broken piece of plastic outer was still wrapped around so i didnt soot it before. The cable was rusty as it must have had so much crap/rain pouring in. The gear drive gets greased regularly so im hoping thats not been compromised! Other than that, my cylinder is pretty much marked up and prepared for attack!  This is marked higher than i need at the moment, im going to scribe a line across when i can find my bloomin' scriber. Ill be aiming for a port height of 35.3mm. That may dwindle down to 35mm, depending on my accuracy. But that will still be ok giving my BD suited to a little over 8000rpm 0.1mm packer: = 25.4° BD - suited to just under 8000rpm = 178.35° exhaust duration Trans, 127.55° Any bets on how long before i edit this post? |

|

|

|

Post by sime66 on Mar 15, 2015 9:44:36 GMT

I saw this last night, vespasco, and I see it remains unedited - well done!

I'm going to get a lot from your before and after port-work; it is a job that fills me with trepidation.

I see you found some leaks too; I suppose, long-term, it's good that you've found some explanation for your pinking etc., but I'll sit back and take it in when the clever chaps chip in.

That spot there on the cable is where mine went too, then the water gets in and it all rusts up; I won't ignore a kinked front cable again - best nipped in the bud.

|

|

|

|

Post by pxguru on Mar 15, 2015 10:30:45 GMT

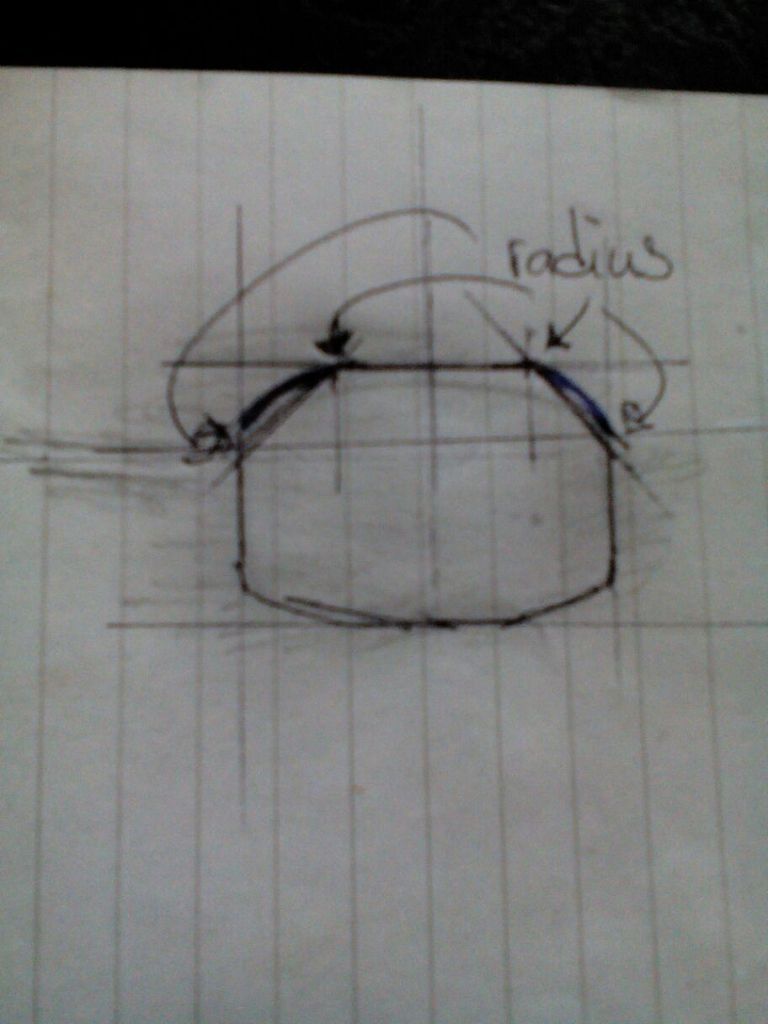

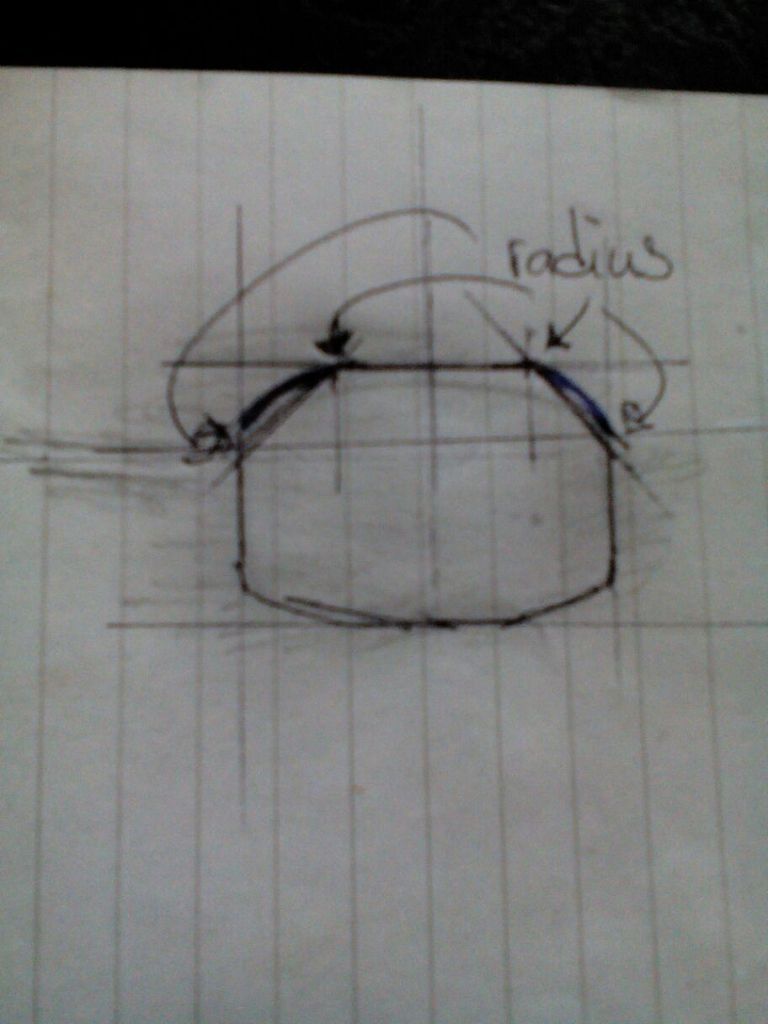

The barrel fell off again! Make sure that line across the top of the port is straight. Port needs to all open at the same time. If you have time post a rubbing of the port to check the shape. Looks a bit over droopy at the sides but maybe better suited to your needs.

Numbers are more suitable to your transfers and about the minimum you can get away with. Not sure about the excess of 2 stoke oil but see how it is when the BD is ok.

|

|

|

|

Post by vespasco on Mar 15, 2015 14:23:11 GMT

Hahaha! Yup! Those cylinders studs dont take much abuse and the cylinder fell off suddenly, yesterday!  There was no 'strong' kink on the cable, it comes out of the hub area straight and its not excessively bent round. Its lasted over 18,000 miles so cant complain! Just wish id spotted it sooner! Im quietly confident the pinking was due to the head leak. The line is straight across top, same width as transfers. And the template i used was first folded in half and cut, so its proper symmetrical! I can only imagine the seemingly excessive 2 stroke oil was due to being too rich with the jetting, over compensating for the pinking, which probably made it worse!!? Anyway, Dremmel time...... *edit! Heres the port shape. Just a quick sketch up.  Originally i was aiming for straight at the top with a large radius all the way to the sides, as per existing. (Shown in blue) Or would you say keep those straight too and just small radius the 'joint' Before: After will come later.....  |

|

|

|

Post by vespasco on Mar 15, 2015 20:11:28 GMT

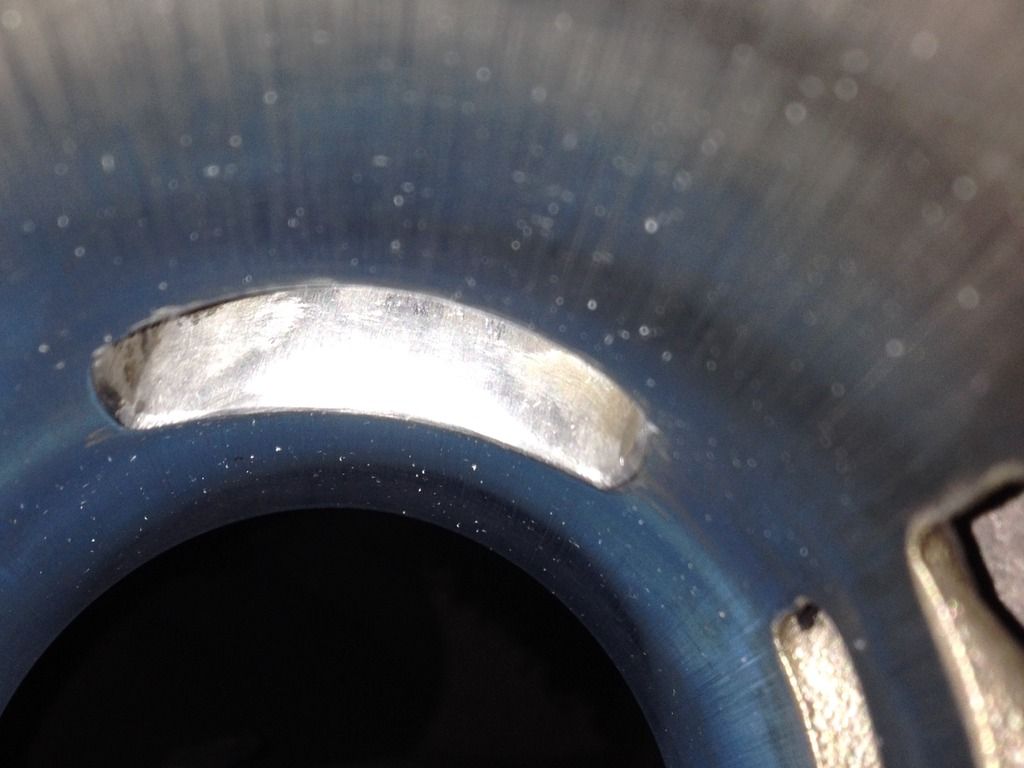

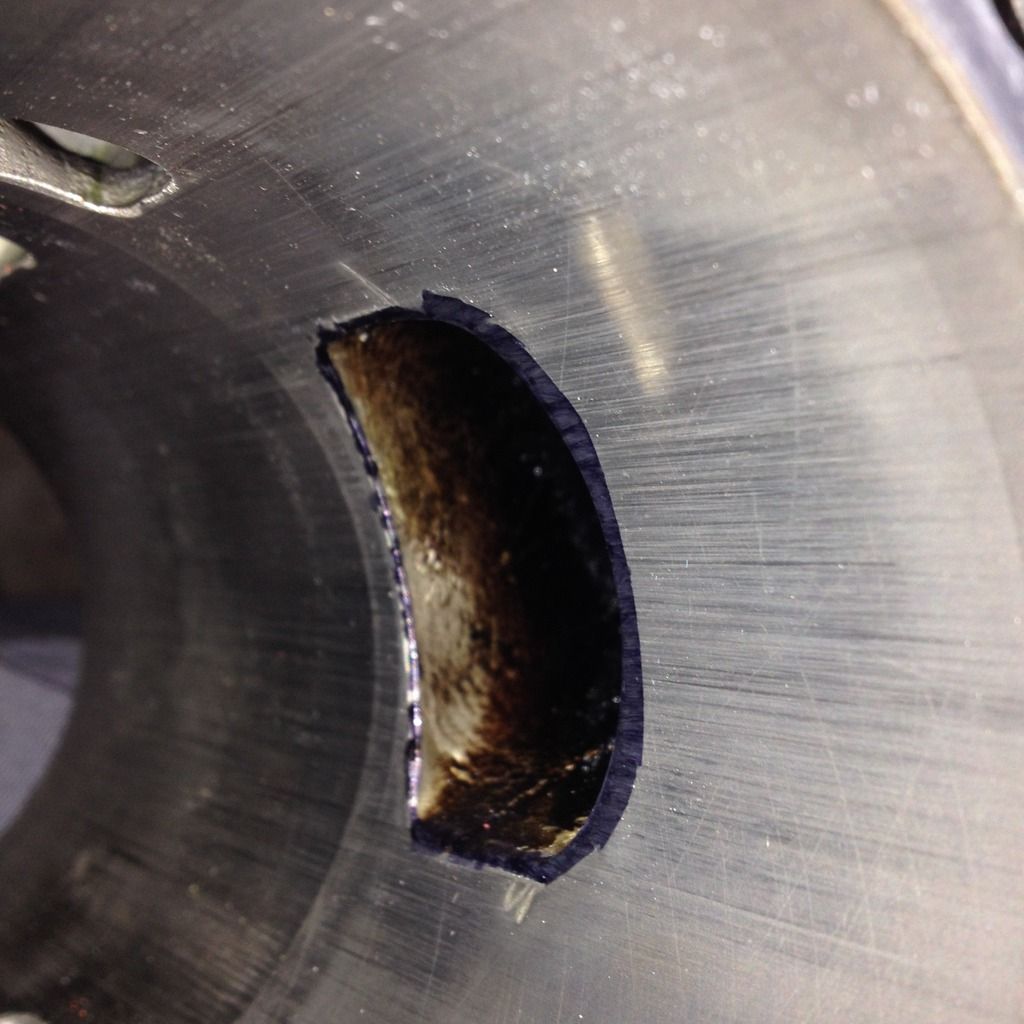

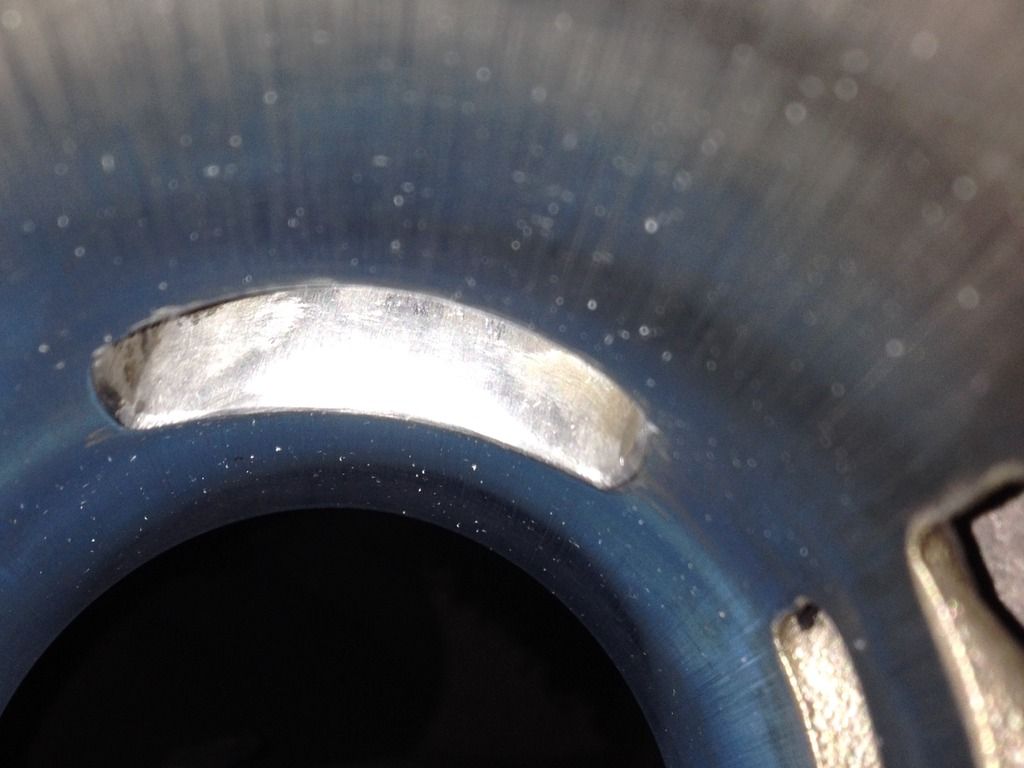

And heres a rubbing of what i ended up with..  Not quite the straight edge i hoped for but still ok  Heres 'during'...  This is as far as i could reach with that small stone in my dremmel and as that stone got even smaller it got more difficult to keep it smooth. I taped all the ports up  Its all bevelled and smoothed off. I just about smoothed out the ridge i created at the top of the port, by using a nice flexible, plastic tooth brush, the handle wrapped with some 240grit. Now I just need to give everything another thorough clean, then re assemble! I may even pop a 0.1mm gasket in there!!?? This time when i reassmeble, im going to leave it over night for the sealant to go off properly before i try to start it!! Theres nothing to see here, move along.....  |

|

|

|

Post by sime66 on Mar 15, 2015 21:09:16 GMT

Haha! Yours is droopy at the sides – glad you’re getting a good tellin’ while my progress is temporarily halted. I was thinking about taping up inside my barrel too, to prevent unfortunate skid-marks. I’m waiting to see what’s said about your radiussing question, although when I do mine I have very little to play with anyway. I’m also wondering how you’re going to get it so perfect and neat, cutting backwards, half-way down the barrel; I’ll be glad just to get something that passes inspection without ballsing the whole thing up. Very much looking forward to seeing the progress.

Edit – before even posting!! You’ve done an update whilst I’ve been composing my posts, but I need to have a good look at it; I’m impressed with how neat it all looks! Anyway, I’m not really contributing, just watching what you do and what comments and suggestions you receive, so I’ll keep my nose out and watch quietly……………

|

|

|

|

Post by pxguru on Mar 16, 2015 5:49:58 GMT

liking the swarf pictures  Thats enough on the height and shape at the top. The sides of the port still need work if you havent put it back on yet. The sides of the port only need a really small chamfer (almost nothing). Top and bottom have a much bigger shallow chamfer to be sure the rings dont catch and wear. It should be possible to put a steel rule from the barrel lining to the exhaust stub and see no high spots. While its off. Are your transfer entry and piston ports all ok? |

|

|

|

Post by vespasco on Mar 21, 2015 17:06:57 GMT

Update: Cylinder is back on. I used a 0.1mm packer in the end. Just to help prevent any leaks more than raising the barrel. Im happy with all the ports. They're all nicely chamfered from the factory...and with my limited equipment i dont fancy dremmeling anymore nikasil. The piston inlet all lines up.. I made a little adjustment last time to smooth it all out. Ive been following simes thread too, picking up on all the little details. The only thing im not so happy with is the finish on nikasil lining at the edges but im sure that will be ok.. Time will tell. Too late now anyway! Im happy my chamfers are ok. Its back together and running. This time i took it easier for longer! Immediately i noticed it sounded like its normal self again! (Just a little louder than stock). That was very promising! The smile was back on my face hearing that motor starting to sound smooth,quiet and sweet again  Before it just sounded awful! It sounded sick! I refrained from opening it up, just pottered around at no more than 1/2 throttle. One reason for that is im sure the MJ is too large. Now i can finally hear the motor running nicely i can concentrate on the jetting. Its nice and smooth but definitely too rich, taking a while to pick up and a flat spot around 4000 - 5000rpm and it also took a few more kicks than usual to start it. It has the 138MJ in atm. So i will try 135, then a 132. My speedo doesnt work (i need a new cable) but rev counter does. I had no joy bidding on a newish second hand Pinasco kit  It was advertised as for long stroke too!? I didnt realise pinasco made this (old style cylinder, like mine) ali cylinder for long stroke? I have a feeling its just the head that could be different? Although i have seen one with a higher exhaust port than i originally had but didnt know if it was a pinasco modification or diy...(i saw pics/details only) That kit i bidded on went for around £180!! People are mad!? By the time you replace the broken piston ring it will be more than a brand new one!!!! (from Europe) |

|

|

|

Post by vespasco on Mar 21, 2015 20:49:43 GMT

Heres the latest/final figures....  |

|

|

|

Post by sime66 on Mar 22, 2015 20:22:06 GMT

Watching this, vespasco; nice numbers too. Nothing to add, but taking it all in.  |

|

|

|

Post by vespasco on Mar 22, 2015 23:25:45 GMT

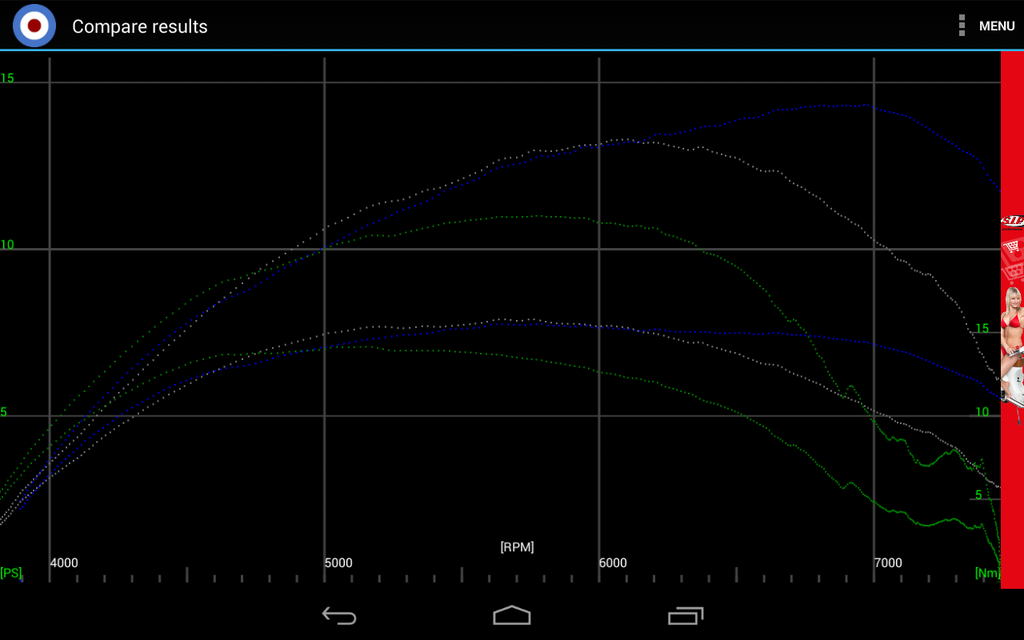

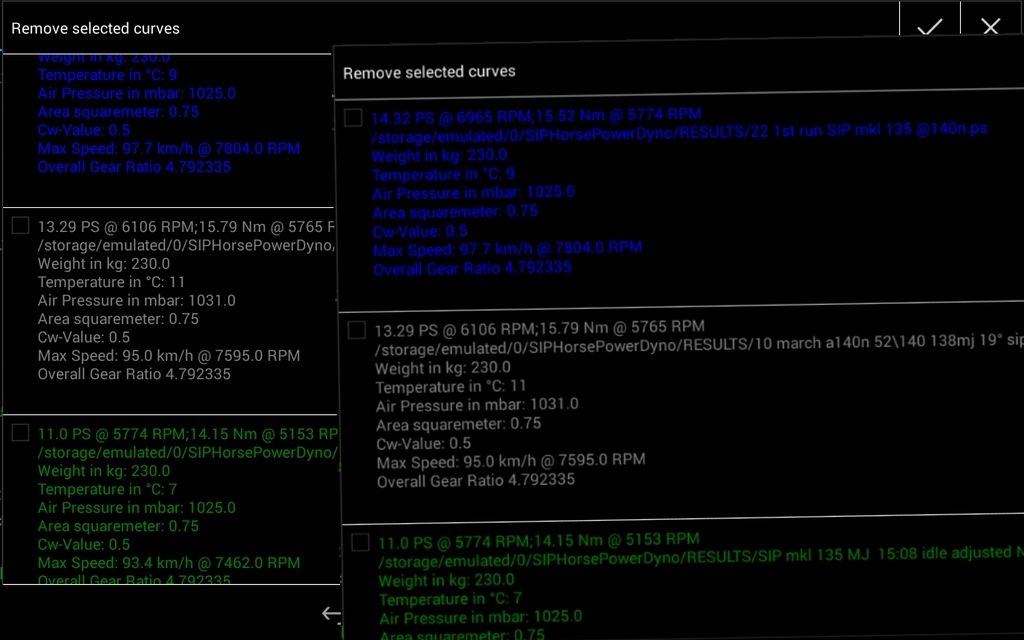

I took some MDynos today. Will post results later. Or will post a comparison of the effects of raising the exhaust port bit by bit. They clearly show how much further it revs out and the shape of the curves are much better The BlowDown is 25.4° (+/-0.5mm measuring). According to our guides and gurus this is suited to around 8000rpm. Which was exactly what my speedo/rev counter topped out at !!!  ऊँ The GPS in the MDyno gave 99.5kmph as a top speed @ 7951rpm. My speedo/rev counter hit 8000rpm a couple of times which matches the gps too.. Its certainly never been there before!! (The speedo cable has broken so i only have rpm as a guide for now) Thats given me something to aim for anyway. 100kmph on the MD. It still needs a little tweak. Im still deciding on which pipe to use...SIP mkl or mkll !? The mkll is still fitted for the moment. The mkll certainly settles the motor down and doesnt hint at pinking but i can really start to hear and physically feel the motor start to work at over 6000rpm It does feel smoother than the mkl upto around 5500rpm The max rpm were the same but the mkl keeps it up for longer (fnarr! fnarr!) with more power  And they sound sooo different. Mkl is more like a lion Mkll sounds more like a nippy, little 2 stroke marycat. Im trying to figure out exactly how and why that happens. Whats the difference in design of the inards of the sip mkll? Oh! Secret??! Its got to be the end cone of the expansion pipe and the small diffence in tail pipe!? I still plan to play with my growler too you see! :0 (My diy expansion pipe) Get ya hands off me growler! Ggrrrrr!! I plan to copy the T5 end cone this time, instead of the more usual stock piaggio 'stub/pipe with holes' idea. Im starting to get used to having to use 3rd gear more too. To help wind it out a bit more for the change upto 4th. (I used to leave it in 4th pretty much all the time) Its quite possible i could now benefit from a 36 tooth 4th gear  ? The 135mj i settled on is a tad rich for the sip mkll. 132mj felt right on the ragged edge, hence the 135. I may even have a little room to advance the timing a tad aswell!  Ill be updating... |

|

|

|

Post by pxguru on Mar 23, 2015 9:12:38 GMT

Must be feeling much better now  All the numbers sound like they have worked out well. The rpm is where you need it for your transfers, I think no need to touch that anymore. The MD comparison will be interesting to demonstrate the change in power curve that a few degrees can make (as it gets close to correct numbers). A few degrees makes no differance at all for barrels that are way off the mark to start with! Will also be good to see MD with an expansion exhaust on (dont forget to up jet at least 5), would expect to see power coming in later but a sizable power increase at the top. Not sure about your gearing. 8000 rpm in 4th would be a lot more than 100km/h. I guess you were talking about 3rd gear  Timing at the max that doesnt pink and get the jetting right and you'll be done for the summer! |

|

|

|

Post by vespasco on Mar 23, 2015 15:10:52 GMT

Yup! Im liking that! And yes i was talking 8000rpm/60mph+ in 3rd gear  I could have tried an Polini pipe but knew i wouldnt keep it on so didnt bother, instead deciding to concentrate on what I wanted, a stock looking pipe. And anyway, i turned the pipe into a mandolin, right H  I cleaned out my diy pipe today. Sounded like it was rusty away inside with all the bits i could hear rattling around when i shook it. There was actually a load of paper, foam, a plastic packer, a cable sleeve end! some rat poison, and a dead mouse who picked the wrong place to hibernate! So when i have time, ill give that another go. Just for fun. Im not expecting it to be perfect. I will post a comparison dyno graph when i sort one out, soon - ish! |

|

|

|

Post by vespasco on Mar 24, 2015 23:47:08 GMT

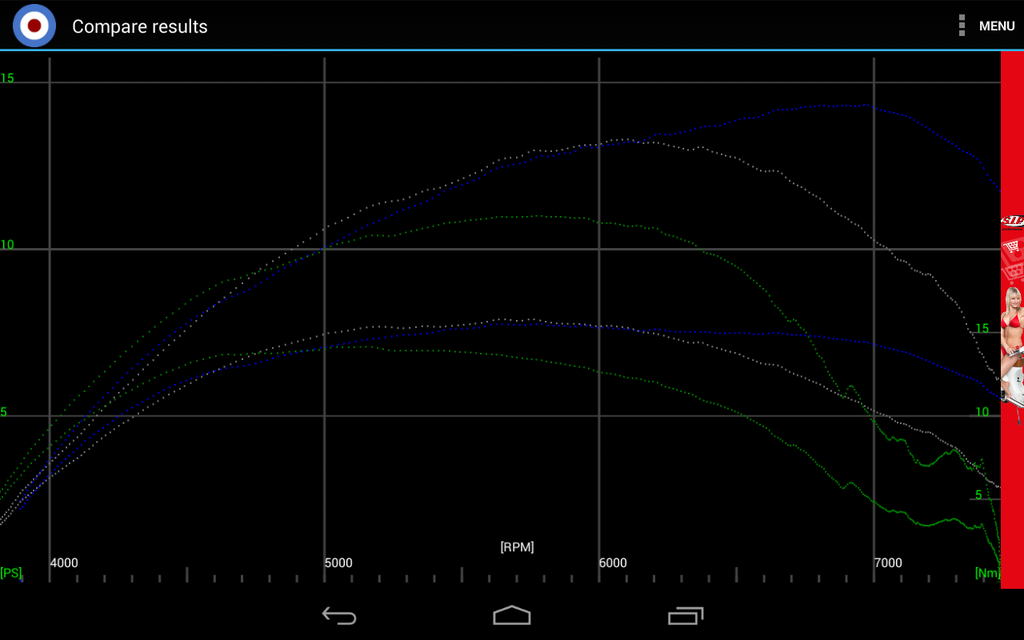

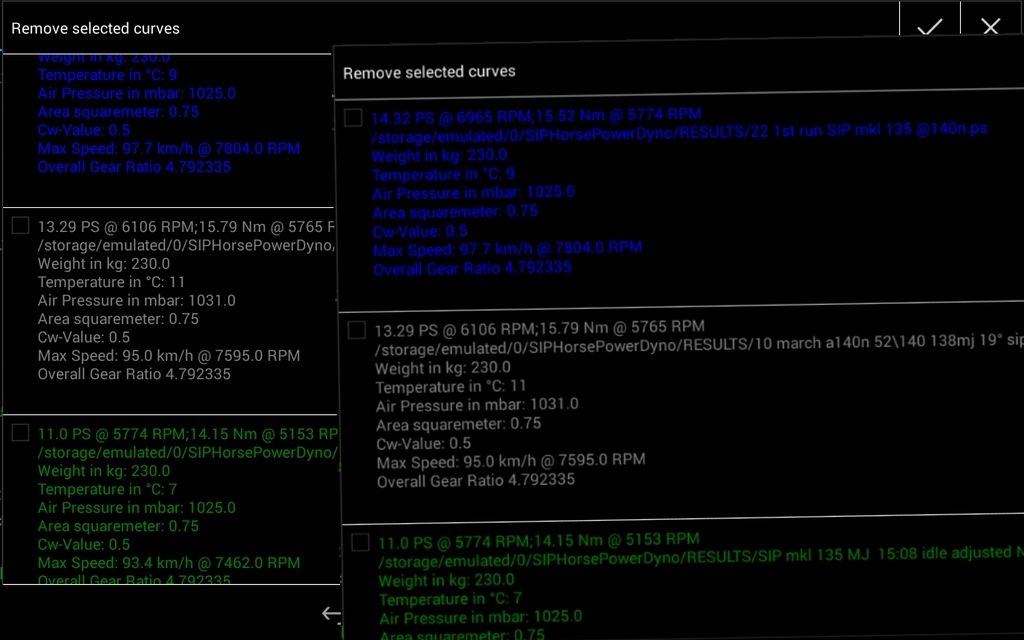

These are not necessarily the best curves i recorded but they show very well the effects of raising the exhaust port The fist smallest green curve is no modifcation. 2nd grey curve is exhaust port raised slightly Largest blue curve is exhaust port as it is now. Raised by 2mm It has actually revved out to 8000rpm, just. Which is exactly what the BD is tuned for!  Note, i do not loose anything low down, the curve remains the same low down. I only gain,gain,gain  *Edit I should add that these results are all made on a mobile app not a 'proper' dyno. The PS and Nm figures may or may not be accurate. But im happy the curves are a good representation of whats going on. |

|

|

|

Post by henri on Mar 25, 2015 8:47:18 GMT

when ya try the other pipe make sure nobodys behind when ya start it , as mouse sh*t in the eye at 50mph will sting abit , H

|

|

|

|

Post by pxguru on Mar 25, 2015 16:01:05 GMT

This does look really impressive. A big wad of top end gain with no bottom end loss. Good job!  I remembered today what you mean about keeping the standard exhaust. Yesterday I brought a completely standard year 2000 PX200 (Near same but different colour from my polossi). Been riding it today. Was really nice to remember how they go and sound. Will be my next project so wont be slow for long  |

|

|

|

Post by henri on Mar 25, 2015 17:15:49 GMT

that is a nice gain from grey to blue at high rpm , all this is tempting the "dremel devil" in me , get the behind me temptress ,

an talkin of mandolins ,you aint got a pk front drum in your "shed of many hidden treasures " , H

|

|

|

|

Post by vespasco on Mar 25, 2015 17:27:24 GMT

I couldn't (maybe wouldn't!?) have done this without you guys! So a massive thanks to all involved  I'm impressed by the graph myself! I was expecting maybe a little drop in low down range when i last raised the port but i think its about right. Actually, its exactly what i (we!) tuned it to, on the BlowDown  So those rpm/port duration figures seem pretty good to me. I'll be waiting with anticipation to see what you do to this lucky motor guru ji I bet you wondered what happened (or didnt) when you opened the throttle on that stock PX! Hahaha |

|

|

|

Post by vespasco on Mar 25, 2015 17:35:34 GMT

Oops! I missed your post there H Yeh go on go on go on Get ya dremel out. You know you want to  Sorry, i dont think i have anything for small frame left. And i sold my last P200 motor today! Thats was a great motor! I almost regret selling it but hey ho! Well at least its going to get used again now:) Someone else can enjoy it  |

|

|

|

Post by sime66 on Mar 26, 2015 6:29:25 GMT

|

|

|

|

Post by henri on Mar 26, 2015 11:08:29 GMT

beers on you then , happy for ya ,H

|

|

|

|

Post by vespasco on Apr 5, 2015 21:15:26 GMT

Update. Its still been randomly pinking. Not quite running right/randomly sounding much louder and pinking at 280°f !! Which is quite weird, as when its running well i would max at 300°f and be ok Temps have been as high as 330°f and pinking. Im not recommending it! (Although my sensor is tapped directly into the head, so will read hotter than most). Dont panic! It was only for a very brief moment to help me conclude a safe running temp....which is now 300°f @ WOT with the sensor IN the head, compared to what it used to be with plug ring, maxxing out at around 230°f @ WOT or 210°f on a cylinder stud. Heres a list of things im not/wasnt entirely happy with; Air leak...carb or head, or even the crankcase. Ive been re torquing the head and carb after all my long runs (after its cooled down) Loose exhaust/stub. Its only the spring holding it on now - i was wondering, if when it was ok, it would be quiet, when it became louder, it would start to pink @ 280°f... Could the lose pipe on the ali cylinder stud be the cause? Ive read conflicting evidence on that subject... Any comments welcomed ..? Like, should that joint, very close to piston, be sealed ideally or??? Ignition pick up moving/rubbing on inside of flywheel - ive finally fitted the new (Piaggio) ignition pick up (not coil) which didnt actually fit at first (on my Motoplast stator plate). I had to file it down so it didnt rub on the inside of the flywheel. Fitting of the BGM fastflow... (Or maybe just coincidence i fitted it at the same time as the rebuild) Im not entirely sure if ive got an occasional fuel shortage or what it is? It happens sometimes when its still warming up. It feels like it wants to nip up. Maybe i need to take it even easier for more miles!? And tonight , when coming home, after it had been fine for an hour of trashing it, i went WOT again and it fell flat on its ass and kinda bogged, lack fuel..went to 1/2 throttle - ok. Wot - fuel starving  ? I have a si26 on order ;D hopefully this will also improve things. I will be attacking that with various drill bits and small files  There is something ive noticed that i havent before..... When i shut the throttle completely, it doesnt fire! (Give it a tiny tiny bit and its ok) The cable and idle are where i like it and have it, with no play. Slide set to 'just' open. Is it just a case of setting the idle revs higher on the slide? Im not going to worry too much just yet...as it will soon have a si26 on it but im wondering if its the port timing thats affecting it. New speedo cable fitted - i got sent the wrong one but dealer came good and sent me a replacement and a free tank cap seal that i needed so happy days  good on him  Tyres pumped Another load of grease and oil here and there A new battery is on its way. So with a new carb im soon going to try And ive still to try my own diy expansion stock pipe (any ideas on a name for it)!? Once ive decided on which pipe im going to settle on then its good to go.  Or is it?!?!  ! Time will tell but It didnt pink this evening after all the little tweaks but that last little 'fuel starvation'?? issue i got just before i reached home bugs me... I notice it more (or maybe total coincidence) when fuel is on reserve... (Which, with the BGM FF is more like 50/50 - on/reserve. Does anyone know how i could alter the reserve capacity on the BGM , or even the stock tap? |

|

|

|

Post by pxguru on Apr 10, 2015 2:52:08 GMT

You might have cooked the plug when you were thrashing it. Sometimes that can make it run funny.

The exhaust must seal at the stub. With lower performance engines and 4 strokes its not so important but with more tuned/higher compression, the extra air sucked in the exhaust will affect the running and will not be consistent. If you can't clamp it tight use exhaust sealer.

If it doesn't cut out when you shut the throttle, then its not so bad. Pilot jet big number (air hole) might be too big.

|

|

|

|

Post by henri on Apr 10, 2015 8:26:46 GMT

to lower ya reserve capacity you'd need to cut the shorter of 2 pipes in top of tap down a bit ,longer ones on stock tap is a breather tube ,an as guru says if youve any doubt about plug bin it , once cooked there toast an can get funny if theve been flooded , H

|

|

|

|

Post by vespasco on Apr 21, 2015 21:56:00 GMT

Update: Im just about managing to find the time to get the Vespa running sweet...er. And it also needed a little tlc elsewhere. Its done about 20k with 2 x different motors (i changed speedos, too, cant remember exactly). Most of those miles would have been WOT wherever possible! And with the Pinasco motor it would have taken a hammering everywhere possible. So its done pretty well for an old timer  Ive done a few more things. I couldn't get it to stop pinking after the mods i done..... My pinking problem was down to my BGM Fast Flo tap but only when i ran on reserve fuel levels. I had another one sent to me FOC, tried and tested. It was better! Max temps were 20° lower too!! Changing from ON to Reserve was also quicker but it still suffered fuel shortage/lean mix as soon as i used reserve. Not as bad but still bad enough. It didnt stop me from taking it for a long run on dual carraigeway. 100 mile round trip. Going fine cruising at 60 - 65mph (1/2 - 3/4 throttle) for miles. Temps ok. No pinking. Very smooth running through towns too. Sounded quite sweet. So then i gave it a blast of WOT and ..... Pinking!! Argh!!! And temps were only 270°f But...it was about to go onto reserve, thats what i put that down to. I took it easy on the way home as ive used 1 litre of expensive 2T in the past few weeks alone. So ive put my old original Rally tap back in. Now the time it takes for the fuel to switch over from reserve is almost instant, compared to slowing down to 10 -20mph from 60mph before the FastFlow cut in again. But ive yet to try it WOT to see if its cured it. I also noticed some minor differences in the taps; The outlet for fuel pipe is slightly higher and angled down on the Piaggio Rally tap than the BGM FF. The outlet also has a wider internal diameter outlet for the fuel pipe (but im led to believe its the inner feed hole that determines the max flow rate) Reserve on BGM is higher/more capacity Large brass breather pipe on piaggio Theres also a fuel 'debris' trap under the stock tap. There isnt one on BGM.  The actual reserve pipe is fitted inside the mesh filter. How do you remove the filter to cut down the reserve pipe? Ive a feeling they're sealed in?  (I dont live in a swamp...they're my gloves, not my fingers)! I also had ignition problems recently. Fitted a new pick up. Fine for a while. Started with 1\2 a kick! Then things started to die again I can only guess it was the ignition coil, which I'll replace at some point for a spare. I ended up going through the whole scoot with a multimeter. Giving it a good service  Changed a few fraying terminals. Slightly changed the DC wiring too. Although its been no 'real' problem, this side of the system was badly designed (by me)! Now its much nicer  New bigger battery. I fried the last one. And i made the battery holder larger for the larger battery. Ive also found a new place for my 12v socket, near the hook under the seat. Checked CDI and stator. Stator /coil still rubbing on inside of flywheel although id checked it was ok beforehand. (I had to file down the pick up for it to fit which rang alarm bells). The pick up measured at 112 ऊँ's when i fitted it. It lasted a few miles before it went 'kaput' and measured under 90 ऊँ's, same as last one.. Its Sods Law, as soon as i sold my lovely spare great condition engine, i now need it and all those spares! Including the cases!! :0 I bit the bullet and ordered a BGM stator and CDi. Now fitted. No more problems. My ducati cdi is still ok. That will be my spare. I was thinking i could have wrecked my crank for a moment but no! Phew! Mec Eur - cheapest and the best! Then i swapped carbs from a stock dellorto/spaco si24 to a spaco si26 (measured @ 25mm)! I had some fun with that! I tried a different slide i had to start, a No.5 (by malossi)!? With just a tiny progression cutaway on top of front corner. Pictured at the bottom of the first pic…..  No. 5 slide at the top  I statted with 55/160, BE3, 160, 138 sip MJ. I couldnt get the idle set up at first. 10 turns out to get it somewhere near! WTF?! It ran like this but not so well. I noticed, inside the idle mix screw hole in the body of the spaco carb, it doesnt have the tiny little cut out for fuel flow like the dellorto has, preventing fuel from flowing. Have a close look in there and you'll see what i mean, at least on a dellorto anyway. The stock sized spacos by dellorto have this notch for fuel flow. I think because the 26mm is a spaco own brand they must have forgot this tiny detail!? I didn't have my drill or bits with me so..... A little hammer, a tiny screwdriver-cum-punch and some welding tip cleaners sorted that out. Although it took an hour. I never thought id be adjusting the most finely tuned part of the motor with a hammer and punch!! But it worked! And works well. The jewellers loupe got well used! Cleaned it all up. Now its back to within the normal 2 1\2 turns out range and also cuts out if screwed fully in. (I couldn't get a clear pic). Theres still a hint of ignition advance to be had i think  ive yet found the time to try. Its well worth finding the limit as anything over 20° gives me great acceleration. And its 19.5° atm...so close! Im still tempted by the Khepher CDi. Luckily for my wallet theyre out of stock atm. Ive noticed another little oil leak through the cases. Either through a bolt or case joint i think. Time for a new motor??/ well time to find some new cases anyway. I keep repairing those poor cases. Time for a new set. Enough is enough. Maybe as a stock motor and more tlc it will be ok. Brake pads are the next thing to do...theyve taken a real hammering!! Any recommendations on brake pads??? I was looking at the newfren 'aqua' type. Any comments? Im not into anything thats going to prematurely wear my hubs down. WANTED: my old engine back  .....oh well... WANgerED: my engine cases WANtED: any vespa 200 cases. But not cosa. "Wait for the edited version. I hear it's much better" |

|

|

|

Post by henri on Apr 22, 2015 7:45:15 GMT

the tap filter is a tight push fit into the body an usually has a brass clip round breather tube to hold it aswell , ive a dismantled 1 an will take photo to show ya ,the tubes are push fit aswell ,if removed an loose can be swaged out with a punch an firm hand pressure to fit tight again , will re-read post again an take in detail ,an comment later if ive any idea ,

oh, an newfren's my usual choice of shoe ,not used aqua's , yet tho, what makes em aqua ,grooves , dont think they will wear drums faster ,thats the race/harder types deal usually , H

|

|

|

|

Post by sime66 on Apr 22, 2015 18:04:26 GMT

That’s an awful lot of info you’ve squeezed in your post, vespasco. I’ve got no idea about these fast-flow taps, but noted with interest the lower temperatures; might be good to know later. Re-doing stator ignition coil and pickup are on my to-do list; I’ve got the stuff now (checked on arrival: pickup=116, ignition=543), but whilst looking around was surprised how cheap the BGM stators are too. I also made a mental note that there’s some good info in your post on the Spaco 26. I also noticed mine was actually 25mm. The bit about the drilling inside the idle mix screw hole is something that will make more sense to me when I re-read with carb in hand to follow it better. I’m just picking up on this timing vs acceleration (vs rpm) thing; you and Henri have both mentioned it recently and pxguru has mastered it, so it’s got me curious now . I read-up on a couple of forums about how and why these programmable CDIs work too, which was interesting, but quite involved – nice subject to look at sometime; there’s more on the to-do list than hours in the day at the moment, especially when the suns out! I sent you a PM earlier about some P200 cases, but having read your post properly now, I don’t think they’d be of much use to you. I use the grooved Newfren; I hadn’t heard them called AntiAqua before, but that does seem to be the ones: “grooved for removal of moisture and dirt from the drum”. I see also you slipped a bit of Prince Buster in! I don’t have much to add really, but after the effort you put into your post it would have been rude not to reply! Well done – words, pictures and sound… (and some good info, too)  (Are the gloves de rigueur in the Eastern Lowlands?  ) |

|

|

|

Post by vespasco on Apr 22, 2015 19:18:18 GMT

I had a gentle go at the tap but wondered if it was sealed in with somehow so left it alone. I didnt want any leaks. The bgm has a grub screw which i undone but again didnt want to force the filter off as there looked like there was a sealer in there too. I may try again on the bgm, nothing to loose, except £13  Yes its the anti aqua 'shoes with grooves' i was thinking of. I think ill give them a punt  The gloves are ok for now but i can only find gloves for 6 fingers around here. (And im still waiting to see Henris space age/Michael Jackson/Nasa gloves  Timing.. Ill see how well i can get my motor to go before i invest over €100 for the programmable cdi..id prefer to be able to do my own mapping which is why the khepher is interesting. BGM - cheapest and the best ! (Well, maybe not the $$ clutches but theyre certainly pretty damn top notch) Shop around even further (italian ebay  and youll find Piaggio stators for around €30!! *(but italian postage is normally expensive) I tried to buy a Tameni stroker crank for £70 from italy but they would not ship to UK  (i asked nicely too) I wondered if the higher revs im now producing was the cause of the ignition coils failing? The BGM stuff takes 10,000 rpm no problem (maybe the piaggio does too??? I dont know for sure). That was the reason for that choice, along with a good price and good quality  Theres not a huge amount to add. Its more of a journal! The porting work has been quite alright. im geting used to it more n more. Im happy with the power i have too,, i do believe ive lost just a little bottom end but nothing i cant get back from altering ignition/jetting. Im also still running my homemade pipe too, so far so good. Its a much much better fit on the pinasco stub, sounds great but my initial feeling is it lacks just a little @ WOT when compared to sip mkll. Its about the same as a sip mkl id say. In the back of mind im wondering if my pipe is contributing to the pinking/getting hot. But ill experimnt a bit more to find out. Heres where an EGT gauge would be ideal!! Question: *edit Taking the sip road as an example....... Which part of the exhaust would i need to alter to allow it to rev just that little bit further? Low and mid range is ok. |

|

|

|

Post by henri on Apr 23, 2015 9:13:24 GMT

the tuned length off the top of my head ,but thats for a expansion chamber type pipe , never had a sip road apart so not sure on the internals/trickery, but am guessing it should be the same , to change it would mean a whole new downpipe with bigger bore/cones an longer length ,but that would move the whole power band up the revs . as youve other pipes i think i'd try swapping them around an see what effect that has on pinking . H

|

|

|

|

Post by pxguru on Apr 23, 2015 11:33:56 GMT

If its running better then the slide thing was worth it! My SI26/26 that will be rescued from the shelf for my tourer, is 25.5mm, which doesn't sound like it but is a lot more area than an SI 24/24. The standard stator/CDI will do 10,000 rpm without any issue. Did you ever get alignment lugs for your head to barrel? If your head is off centre, that will surely cause pinking on a higher rpm engine. I have generally found with the static timing is that it is only really sensitive to pinking if something else is wrong (jetting, head, or porting). Retarding the timing that extra bit will hide some other issue but cause power loss in the mid range. I would put yours at 21 degrees to start with and work from there. Sounds like good progress though. I'll be getting one of the new Khepers for my tourer too. Aparently they will have wifi to a smartphone app! How cool is that?  |

|

and will be used again! (these were plastic pen top lids that happen be a good diameter for this, drilled out to 8mm/8.5mm.

and will be used again! (these were plastic pen top lids that happen be a good diameter for this, drilled out to 8mm/8.5mm.

and will be used again! (these were plastic pen top lids that happen be a good diameter for this, drilled out to 8mm/8.5mm.

and will be used again! (these were plastic pen top lids that happen be a good diameter for this, drilled out to 8mm/8.5mm.

?

?

Changed a few fraying terminals. Slightly changed the DC wiring too. Although its been no 'real' problem, this side of the system was badly designed (by me)! Now its much nicer

Changed a few fraying terminals. Slightly changed the DC wiring too. Although its been no 'real' problem, this side of the system was badly designed (by me)! Now its much nicer

.....oh well...

.....oh well...